Successful Implementation of Hydranautics Ultrafiltration MAX80 in a Rubber Processing Plant in Spain

Successful Implementation of Hydranautics Ultrafiltration MAX80 in a Rubber Processing Plant in Spain

We are pleased to announce the successful deployment of our substitute product, Hydranautics Ultrafiltration MAX80, at a prominent rubber processing plant in Spain. Here is a summary of the project and its achievements:

Customer Background and Requirements

Our customer is a leading rubber processing plant based in Spain, specializing in the production of high-quality rubber products. They were in need of a reliable ultrafiltration system for treating industrial wastewater, with requirements for efficient, stable water filtration that is easy to operate and maintain.

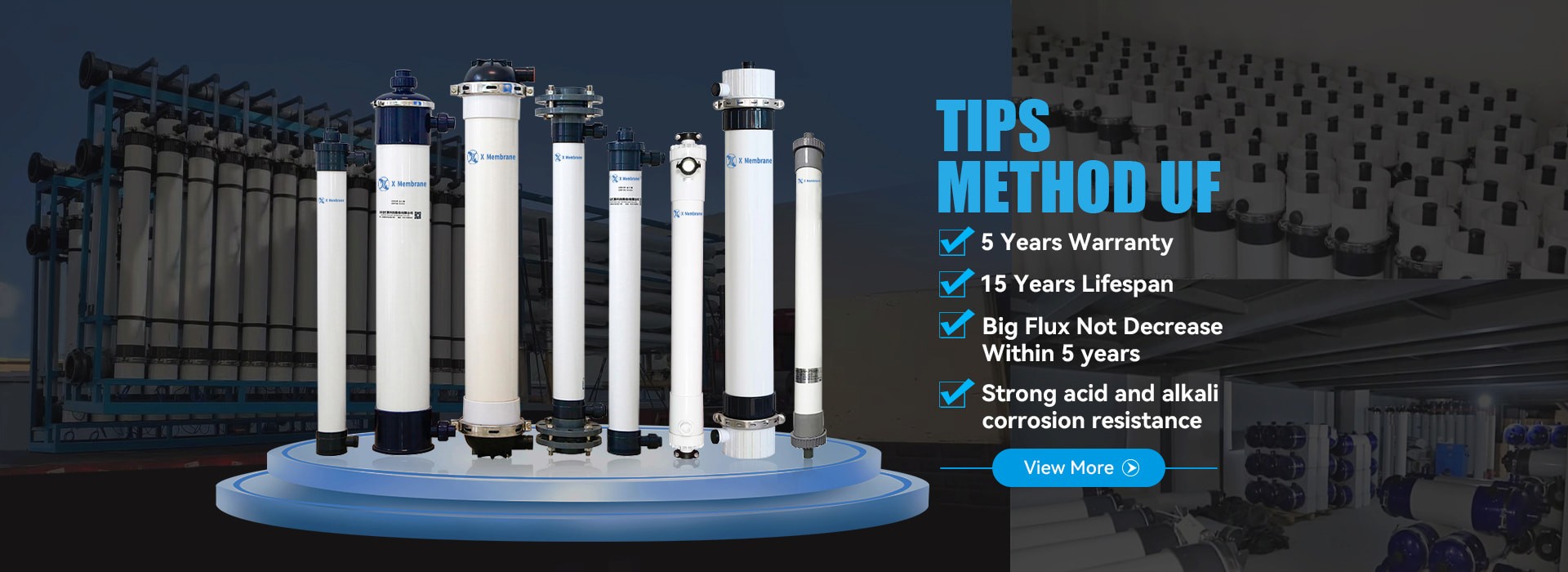

Selection of Hydranautics Ultrafiltration MAX80

After careful market research and product comparisons, the customer chose our product, Hydranautics Ultrafiltration MAX80, as a replacement for their existing ultrafiltration system. This product stood out for its high filtration efficiency, stable performance, and ease of operation, meeting all the customer's requirements and expectations.

Implementation and Installation

Throughout close collaboration with the customer, our team provided comprehensive technical support and consulting services. We jointly developed an installation plan and ensured smooth execution of all installation steps. With a professional installation team and detailed operational guidance, Hydranautics Ultrafiltration MAX80 was successfully integrated into the customer's existing treatment system.

Operation and Maintenance

Upon completion of installation, our team conducted thorough training sessions to ensure the customer is proficient in operating and managing the Hydranautics Ultrafiltration MAX80 system. We also established a regular maintenance schedule to ensure continuous stable operation and maximize system lifespan.

Achievements and Feedback

Following the implementation of Hydranautics Ultrafiltration MAX80, the customer provided highly positive feedback. They reported significant improvements in filtration efficiency, achieving the desired water quality standards with ease of operation. The customer expressed high satisfaction with the product performance and the quality of service provided, considering the replacement a wise decision.

Conclusion

This project not only demonstrates the superior performance of Hydranautics Ultrafiltration MAX80 in industrial wastewater treatment but also validates our technical expertise and professional services in the field of water treatment. We remain committed to innovation, providing reliable water treatment solutions globally to help customers achieve environmental goals and enhance production efficiency.

For more information about Hydranautics Ultrafiltration MAX80 or other products, or to learn further details, please feel free to contact our sales team. We look forward to further collaboration!

Language

Language

Network Supported

Network Supported